Newrest joins the ADP group’s Paris-Orly environment alliance

Europe

|Europe

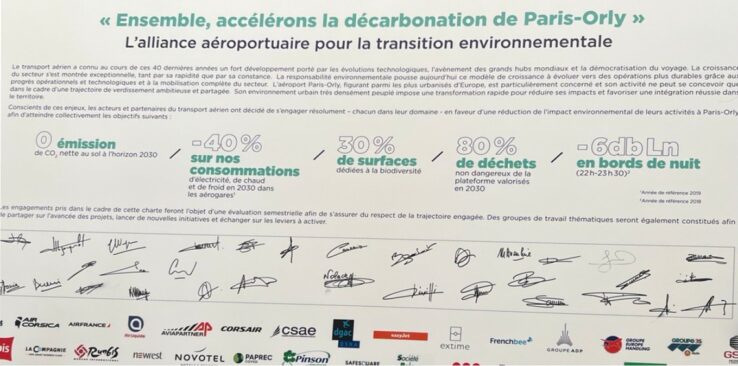

ADP wants to speed up Orly airport’s ecological transition with the creation of an environmental alliance based on five objectives to reduce the airport’s carbon impact by 2030. Some thirty companies have joined the alliance, including Air France, Novotel and Transavia.

Objectives for Orly airport.

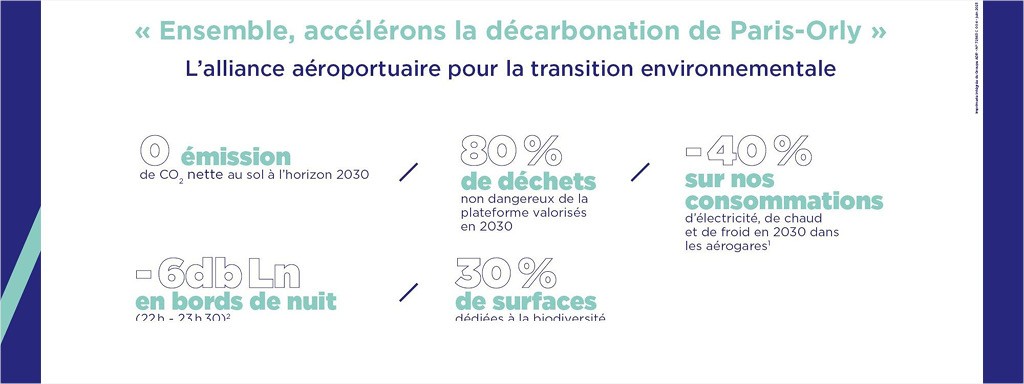

With the aim of reducing its carbon impact as much as possible by 2030, ADP has set 5 objectives for Orly airport:

- 40% reduction in electricity consumption

- Zero net CO2 emissions on the ground

- 80% recovery of non-hazardous waste

- Preservation of 30% of areas dedicated to biodiversity

- Noise level reduced by 6 decibels at night (10pm-11.30pm)

An update is organised every 6 months to keep track of progress towards the objectives.

By participating in this alliance and in line with its CSR charter, Newrest is acting to protect the environment.

Newrest: strong commitments already implemented

The group is already implementing a number of actions based on 5 of the 6 environmental pillars of its CSR charter:

– Reducing food waste

As part of its commitment to reducing food waste, the Orly unit is working with waste management service provider Les Alchimistes. This company specialises in collecting food waste and turning it into compost to nourish the soil. The group also recycles its used edible oils.

In addition, Newrest Orly works with the food bank to organise a weekly collection of products that are past their sell-by date.

– Improving the waste management strategy

The Orly airport unit has set up a sorting system. The group works with 3 service providers: Les Alchimistes for the collection and transformation of waste into compost, Paprec which processes category 1 waste, non-hazardous industrial waste and cardboard recycling, and Allo à l’huile which collects used edible oils.

In addition to the normal bins, biowaste bins are made available on the unit, enabling them to fill the waste bins for Les Alchimistes. As part of this approach, a special bin for oils has also been set up.

In addition to the sorting carried out by the teams, Newrest has teamed up with CY-CLOPE to recycle cigarette butts around the unit by installing a Cy-Clopeur.

– Developing a paperless process

Newrest has decided to promote the use of tablets in the production area to reduce paper consumption. 7 hand dryers have also been set up in the unit’s toilets and changing rooms.

– Reducing greenhouse gas emissions

To limit its energy consumption, the Group has introduced motion detectors during the impACT project, as well as mixer taps for the washbasins.

The temperature has also been raised in the production area.

In addition to these actions, studies are in progress, in collaboration with Carbuwash-Transdev, to use biofuel for heavy goods vehicles.

– Reducing single use plastics

As part of its plastic waste management strategy, the Group has eliminated disposable clothing in production, staffing and dishwashing areas since November 2022.

In addition to these actions, the Group also organised awareness-raising campaigns on breast cancer detection for Pink October 2022 and held a workshop in June 2023 to raise awareness of the dangers of smoking.

FOR MORE INFORMATIONS :

en

en

fr

fr es

es